Introduction

Infra-Lightweight concrete is a high-performance concrete, which promises durable, sustainable and attractive buildings due to its low dry density as load-bearing thermal insulation. Monolithic structures made of exposed concrete can once again meet economic and ecological requirements. Infra-Lightweight concrete opens new ways to “Baukultur” and the design appropriate to the material.

Projects

Exhibition “Technoscape – The architecture of engineers”

MAXXI Rome, 2022

Technische Universität Berlin

As part of the Technoscape exhibition at MAXXI (Museo Nazionale delle Arti del XXI Secolo), the Chair of Conceptual and Structural Design will exhibit specimens from its own research areas. Models and possibilities of using infra-lightweight concrete and prestressed carbon concrete structures will be presented.

K40

Kleinmachnow

Architect: Baumgarten Simon Architekten BDA, Berlin

Structural Engineer: Weiske und Partner GmbH Beratende Ingenieur VBI

Checking Engineer: schlaich bergermann partner

Cooperation: –

South of Berlin, a single-family house is being built using infra-lightweight concrete and lightweight concrete. In the two-story building, in addition to the ILC walls bearing vertical loads, ILC components are also exposed to bending loads. In addition, the ILC walls also contribute to the building stiffness. An infra-lightweight concrete of grade ILC8-D0.8 with galvanized reinforcing steel is used.

Garage

Berlin, 2019

Architect: Prof. Clemens Bonnen (Berlin)

Structural Engineer: –

Checking Engineer: –

Cooperation: –

REWE

Berlin, 2023

Architect: Baumgardt Franke Architects

Structural Engineer: schlaich bergermann partner

Checking Engineer: –

Cooperation: –

Single family house “Ruppiner Land”

Großwoltersdorf (in planning, completion 2022)

Architect: Prof. Clemens Bonnen (Berlin), BesoniasAlmeida Arquitectos (Bueonos Aires)

Structural Engineer: neubauer + ernst ingenieure

Checking Engineer: schlaich bergermann partner

Cooperation: –

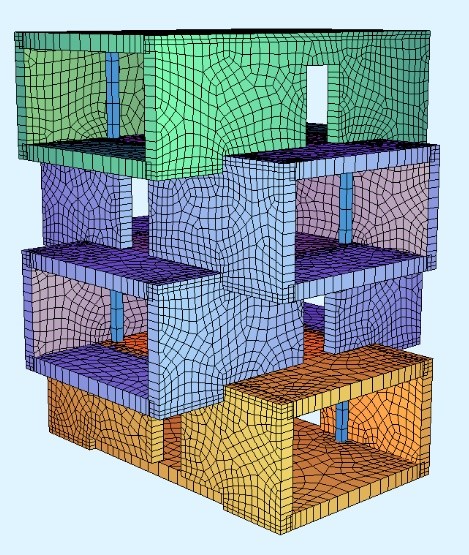

About 60 kilometers north of Berlin, a new residential building is being built for a family of 6 made of exposed concrete inside and outside. The cubically graduated building cubature results from the dynamic combination of differently dimensioned one- and two-storey volumes of reinforced concrete. Accordingly, it has flat roofs in different levels. However, the complex appearance of the result is free on all sides and is placed on the property in such a way that sufficient distance to the public street space and the adjoining land remains. All exterior-facing walls are manufactured to comply with energy saving regulations (ENEV) in Infra-Lightweight Concrete.

Atelier Albert Oehlen

Weidingen (concept study and obtaining of approval in individual case (ZIE))

Architect: Enguita & Lasso De la Vega

Structural Engineer: schlaich bergermann partner

Checking Engineer: –

Cooperation: Albert Oehlen, Anja Axt

For the studio Albert Oehlen in Weidingen a monolithic exposed concrete building made of Infra-Lightweight Concrete with a sloping segmented glass façade with drawstrings made of carbon fiber-reinforced plastic is to be created.

Both Infra-Lightweight Concrete and tension members made of carbon fiber-reinforced plastic offer enormous potential for innovation, but have not yet been regulated by the building authorities. Every innovation carries a risk. In order to minimize this risk, the office schlaich bergermann partner was commissioned by the client to investigate feasibility, permitability and cost framework.

Research Project Technische Universität Berlin

Prefabrication of precast elements made of infra-lightweight concrete for multi-storey residential buildings (ILVO)

Duration 2019-2020

Architect: Anna Mendgen, Chair of Conceptual and Structural Design (TU Berlin)

Structural Engineer: Claudia Lösch, Chair of Conceptual and Structural Design (TU Berlin)

Owner: HOWOGE

Cooperation: Deutsche Bundesstiftung Umwelt (DBU), Transsolar KlimaEngineering, GBJ Geithner Betonmanufaktur Joachimsthal GmbH

Multi-Story Building

Berlin (in planning)

Architect: Barkow Leibinger

Structural Engineer: schlaich bergermann partner

Checking Engineer: –

Cooperation: Transsolar

The “Wohnungsbaugesellschaft Mitte” in Berlin is planning a multi-story apartment building with Barkow Leibinger, schlaich bergermann partner and Transsolar, based on the design of the urban living competition.

https://www.wbm.de/de/bauprojekte/friedrichshain-kreuzberg/wohnturm-aus-infraleichtbeton/

BETONOASE

Berlin-Lichtenberg, 2017

Architects: Gruber+Popp Architects

Structural Engineer: schlaich bergermann partner

Checking Enginerr: Specht Kalleja + Partner

Cooperation: HeidelbergCement

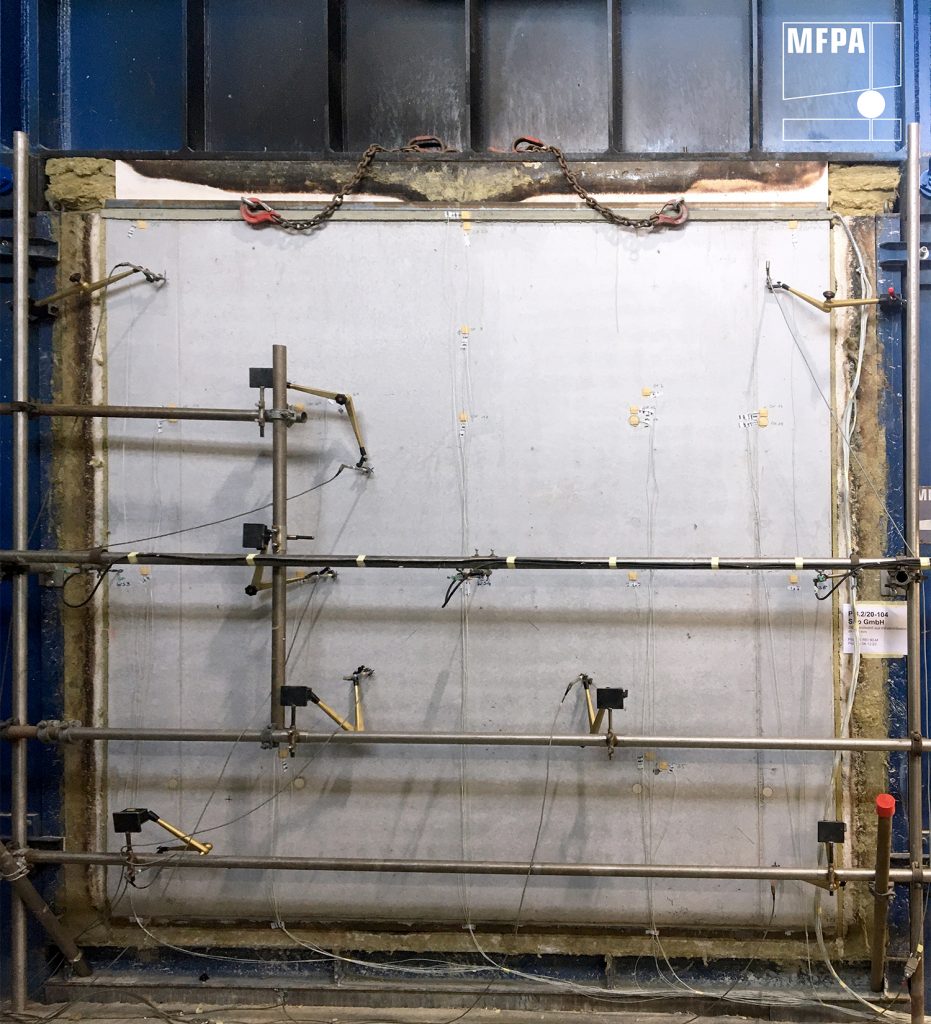

The “concrete oasis” is a single-storey youth recreation center of the youth welfare office Berlin-Lichtenberg. The design by Gruber + Popp Architekten BDA prevailed in March 2016 against five competitors. In the course of granting an individual approval, experimental tests were carried out and a sample wall was produced at the TU Berlin. The structural design of the project was carried out by the Berlin office of schlaich bergermann partner. On December 4th 2018 the “concrete oasis” was opened.

https://www.beton.org/aktuell/news/details/betonoase-mit-infraleichtbeton/

http://www.sbp.de/news/richtfest-beim-infraleichtbeton-bauvorhaben-betonoase-in-berlin-lichtenberg/

https://www.baunetzwissen.de/beton/objekte/freizeit-sport/betonoase-in-berlin-5564052

Competition SMART MATERIAL HOUSE

IBA-Hamburg, Mock-up wall Berlin 2012

Architects: Barkow Leibinger

Structural Engineer: schlaich bergermann partner

Checking Engineer: –

Cooperation: Transsolar

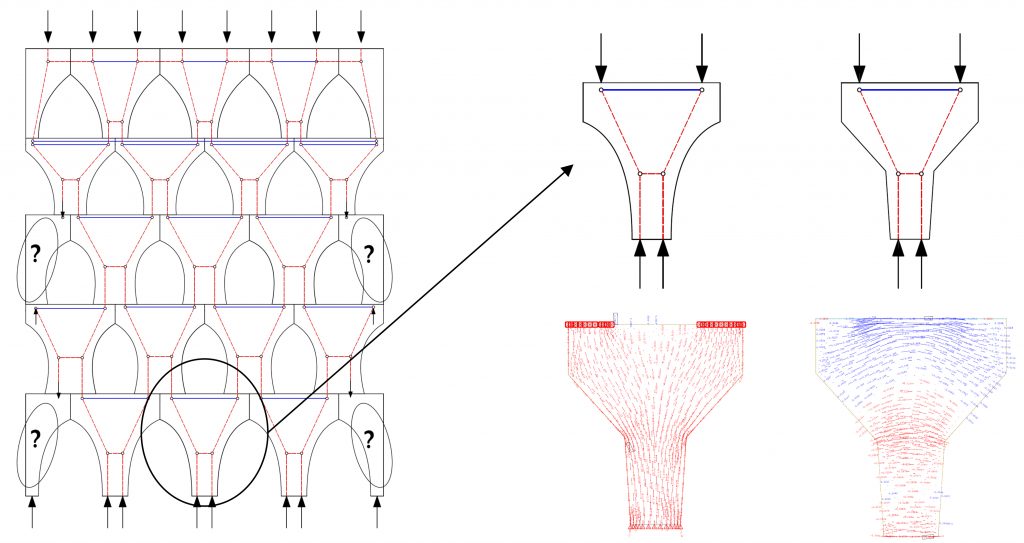

With the “Smart Material House”, as the name implies, the material is in the foreground. The basic idea was to use infra-lightweight concrete as “load-bearing thermal insulation”. The biconcave curved wall panels are not for bearing loads only but for thermal insulation, and also as a heating and cooling system. Here, hoses for the heating and cooling system are integrated. The elements of infra-lightweight concrete has a sufficient acompressive strength for multi-storey buildings. Without additional thermal insulation, plaster or other cladding, exposed concrete construction is possible.

Single Family House

Berlin-Pankow, 2007

Architect: Prof. Clemens Bonnen + Amanda Schlaich

Structural Engineer: Mike Schlaich + Lars Werner

Checking Engineer: Specht Kalleja + Partner

Cooperation: Lichtner Beton, Kasimir Bauunternehmung

The cubic three-story building is made of concrete walls, which has large window openings on the south and north sides. By shifting back these large windows, the structure gains more plasticity. The floor-to-ceiling curtains behind the glass leads to a softness in contrast to the hard concrete surface. A reduced set of colors of gray exposed concrete, black window profiles, white curtains and silver blinds give the house a simple clarity.

https://www.beton.org/inspiration/architektur/objekt-details/wohnhaus-in-berlin/

Video

Interview Mike Schlaich (german)

Interview Mike Schlaich (english)

Interview Regine Leibinger and Mike Schlaich (german)

Interview Alex Hückler (german)

History

Start of the development of a DAfStb guideline

In May, a REWE supermarket with external walls made of ILC opens in Berlin

Exhibition “Technoscape – The architecture of engineers” at MAXXI (Museo Nazionale delle Arti del XXI Secolo) in Rome with contribution about possibilities of using ILC

Publication Infra-Lightweight Concrete article in the “Betonkalender 2021”

Publication of the book Building with Infra-lightweight Concrete by Claudia Lösch, Philip Rieseberg, Eds.: Mike Schlaich, Regine Leibinger

Completion of the ILC garage

Opening of the “concrete oasis” on December 04th 2018.

Various third-party funded projects were successfully applied for and processed from this phase. The third-party funded research in this phase consisted (and still consists) on the one hand of basic research, with results being incorporated into design concepts, and on the other hand of application-oriented investigations dealing with architectural, structural and design issues.

Subsequently, further research was carried out to reduce the unit weight to provide better insulating properties. This resulted in an ILC group consisting of compositions with dry densities of 550, 600, 650, 700, 750 and 800 kg / m³ with corresponding compressive strengths between 5 and 13 MPa.

During the second phase (2010–2014) the original mix design was improved as a first step, resulting in almost doubled compressive strength at the same density. The applicability of the new mix was successfully tested in a precast plant. The result was a 1:1 mock-up wall in the context of the design of the “Smart Material House” by Barkow Leibinger, Transsolar Energietechnik and schlaich bergermann and partner. The design was awarded with the second Global Holcim Innovation Award.

Since 2006, the research activities regarding Infra-Lightweight concrete at the TU Berlin have been going through different phases. Until 2010, basic knowledge of manufacturing and handling was gained as well as numerous investigations to determine the fresh and hardened concrete properties carried out. As a result, a detached house was built in Berlin and in addition to various publications a dissertation by El Zareef was completed in 2010.

Literature

ELSHAHAWI, M. ; HÜCKLER, A. ; SCHLAICH, M.: Strut effectiveness factor and maximum shear strength of Infra Lightweight Concrete (ILC). In: Engineering Structures 286 (2023), S. 116134; https://doi.org/10.1016/j.engstruct.2023.116134.

ELSHAHAWI, M. ; HÜCKLER, A. ; SCHLAICH, M.: Shear behavior of infra lightweight concrete (ILC) with stirrups. In: Journal of Building Engineering 72 (2023), S. 106667; https://doi.org/10.1016/j.jobe.2023.106667

ELSHAHAWI, M.; HÜCKLER, A.; SCHLAICH, M.: Shear behaviour of infra lightweight concrete (ILC) without stirrups. In: Structures 45 (2022), S. 1587–1606; https://doi.org/10.1016/j.istruc.2022.09.114.

ELSHAHAWI, M.; HÜCKLER, A.; SCHLAICH, M.: Constitutive relations and finite element modelling of Infra Lightweight Concrete (ILC). In: Journal of Building Engineering 48 (2022), S. 103869; https://doi.org/10.1016/j.jobe.2021.103869 .

Schlaich, M.; Hückler, A.; Lösch, C.: Infraleichtbeton. In: Beton-Kalender 2021: Fertigteile; Integrale Bauwerke, (Hrsg.) Konrad Bergmeister, Frank Fingerloos und Johann-Dietrich Wörner, Ernst & Sohn Verlag, Berlin, 2021, S. 907–950.

Liu, Y.; Tafsirojjaman, T.; Dogar, A. U. R.; Hückler, A.: Bond behaviour improvement between infra-lightweight and high strength concretes using FRP grid reinforcements and development of bond strength prediction models, In: Construction and Building Materials (2020), 121426, ISSN 0950-0618, https://doi.org/10.1016/j.conbuildmat.2020.121426.

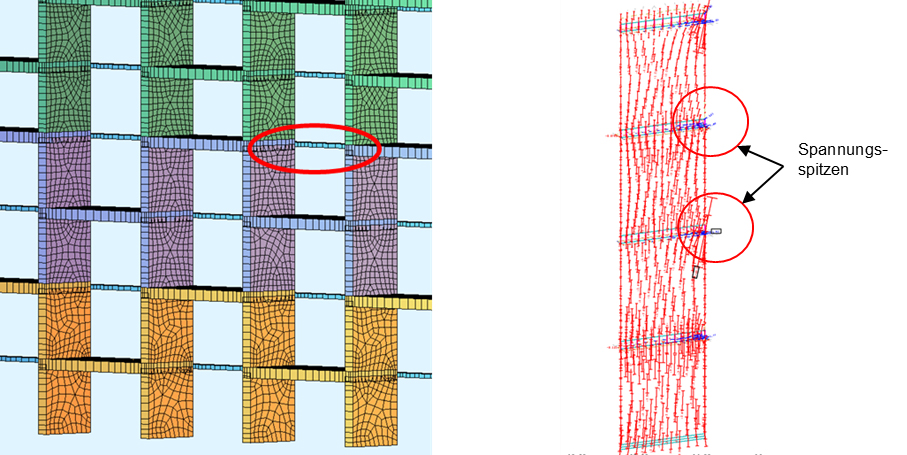

Lösch C; Richter A; Schlaich M.; Structural behavior of multifunctional inhomogeneous infra-lightweight concrete elements. In: Structural Concrete (2020); S. 1–15

ELSHAHAWI, M.; HÜCKLER, A.; SCHLAICH, M.: Infra lightweight concrete: A decade of investigation (a review). In: Structural Concrete – Journal of the fib (2020); S. 1–17. DOI: 10.1002/suco.202000206.

LIU, Y.; TAFSIROJJAMAN, T.; DOGAR, A. U. R.; HÜCKLER, A.: Shrinkage behavior enhancement of infra-lightweight concrete through FRP grid reinforcement and development of their shrinkage prediction models. In: Construction and Building Materials (2020) Nr. 258, S. 1–12. DOI: 10.1016/j.conbuildmat.2020.119649.

Schlaich, M.; Hückler, A.: Infraleichtbeton. In: Der Prüfingenieur 56, Mai 2020

Schlaich, Mike (Hrsg.); Leibinger, Regine (Hrsg.); Lösch, Claudia; Rieseberg, Philip: Building with Infra-lightweight Concrete: Design, Planning, Construction. Berlin: Fraunhofer IRB Verlag, 2020

Lösch, C.; Hückler, A.; Schlaich, M.: Infraleichtbeton – Grundlagen, bauphysikalische Eigenschaften und Referenzbauwerke In: Bauphysik 41 (2019), Nr. 1, S. 1–6

Hückler, Alex; Schlaich, Mike: Structural Behavior of Reinforced Infra-Lightweight Concrete (ILC). In: ACI Structural Concrete. March-April 2019

Schlaich, Mike; Gruber, Doris; Popp, Bernhard: Infraleichtbeton – Leichter als Wasser. In: Deutsche BauZeitschrift (2019), Nr. 2, S. 62–65

Schlaich, Mike (Hrsg.); Leibinger, Regine (Hrsg.); Lösch, Claudia; Rieseberg, Philip: Infraleichtbeton: Handbuch für Entwurf, Konstruktion und Bau. Berlin: Fraunhofer IRB Verlag, 2018

Schlaich, Mike; Hückler, Alex: Infraleichtbeton: Reif für die Praxis. In: Beton- und Stahlbetonbau (2017), Nr. 12, S. 772-783

Schlaich, Mike; Hückler, Alex; Lösch, Claudia: Infra-Light Weight Concrete – A monolythic building skin. In: AUER, Thomas; KNAAK, Ulrich; SCHNEIDER, Jens (Hrsg.): Proceedings of Powerskin Conference. Delft: TU Delft Open, 2017, S. 293–304

LEIBINGER, Regine; Schlaich, Mike; Lösch, Claudia; Rieseberg, Philip; Ballestrem, Matthias: Infraleichtbeton im Geschosswohnungsbau (INBIG) : Abschlussbericht. Stuttgart: Fraunhofer IRB Verlag, 2017 (Forschungsinitiative Zukunft Bau F 3018)

Hückler, Alex ; Schlaich, Mike: Zur Biegung von Infraleichtbetonbauteilen – Werkstoff-, Verbund-, Trag- und Verformungsverhalten. In: Beton- und Stahlbetonbau 112 (2017), Nr. 5, S. 282–292

Hückler, Alex: Trag- und Verformungsverhalten von biegebeanspruchten Bauteilen aus Infraleichtbeton (ILC). Dissertation. 1. Auflage. Göttingen: Sierke Verlag, 2016

Lösch, Claudia; Rieseberg, Philip; Schlaich, Mike; LEIBINGER, Regine; BALLESTREM, Matthias: Infra-Lightweight Concrete in Multi-Story Residential Buildings. In: Economic Forum (Hrsg.): 10th Conference on Advanced Building Skins: 3-4 November 2015, Bern, Switzerland, S. 932–941

Hückler, Alex; Schlaich, Mike: Bond and deformation behaviour of reinforced Infra-Lightweight Concrete (ILC). In: Proceedings of fib Symposium 2015, Copenhagen, S. 116–117

Hückler, Alex; Schlaich, Mike: Infraleichtbeton – Forschung an der Technischen Universität Berlin. In: Baukammer Berlin – Nachrichten für die im Bauwesen tätigen Ingenieure (2015), Nr. 1, S. 21–24

Hückler, Alex; Schlaich, Mike: Low Tech Konstruktionen mit Infraleichtbeton: Diese Außenwand kann Multitasking. In: Deutsche BauZeitschrift (2013), Nr. 2, S. 84–86

Schlaich, Mike; Hückler, Alex: Infraleichtbeton 2.0. In: Beton- und Stahlbetonbau 107 (2012), Nr. 11, S. 757–766

El Zareef, Mohamed Ahmed Mohamed (Hrsg.): Conceptual and structural design of buildings made of lightweight and infra-lightweight concrete. Aachen : Shaker., 2010

Schlaich, Mike; El Zareef, Mohamed: Infraleichtbeton. In: Beton- und Stahlbetonbau 103 (2008), Nr. 3, S. 175–182

Schlaich, M.; Hückler, A.; Lösch, C. (2021): Infraleichtbeton. In: Beton-Kalender 2021: Fertigteile; Integrale Bauwerke, (Hrsg.) Konrad Bergmeister, Frank Fingerloos und Johann-Dietrich Wörner, Ernst & Sohn Verlag, Berlin, 2021, S. 907–950.

Liu, Y.; Tafsirojjaman, T.; Dogar, A. U. R.; Hückler, A. (2020): Bond behaviour improvement between infra-lightweight and high strength concretes using FRP grid reinforcements and development of bond strength prediction models, Construction and Building Materials, 121426, ISSN 0950-0618, https://doi.org/10.1016/j.conbuildmat.2020.121426.

Lösch C; Richter A; Schlaich M.; Structural behavior of multifunctional inhomogeneous infra-lightweight concrete elements. In: Structural Concrete (2020); S. 1–15

ELSHAHAWI, M.; HÜCKLER, A.; SCHLAICH, M.: Infra lightweight concrete: A decade of investigation (a review). In: Structural Concrete – Journal of the fib (2020); S. 1–17. DOI: 10.1002/suco.202000206.

LIU, Y.; TAFSIROJJAMAN, T.; DOGAR, A. U. R.; HÜCKLER, A.: Shrinkage behavior enhancement of infra-lightweight concrete through FRP grid reinforcement and development of their shrinkage prediction models. In: Construction and Building Materials (2020) Nr. 258, S. 1–12. DOI: 10.1016/j.conbuildmat.2020.119649.

Schlaich, M.; Hückler, A.: Infraleichtbeton. In: Der Prüfingenieur 56, Mai 2020

Schlaich, Mike (Hrsg.); Leibinger, Regine (Hrsg.); Lösch, Claudia; Rieseberg, Philip: Building with Infra-lightweight Concrete: Design, Planning, Construction. Berlin: Fraunhofer IRB Verlag, 2020

Lösch, C.; Hückler, A.; Schlaich, M.: Infraleichtbeton – Grundlagen, bauphysikalische Eigenschaften und Referenzbauwerke In: Bauphysik 41 (2019), Nr. 1, S. 1–6

Hückler, Alex; Schlaich, Mike: Structural Behavior of Reinforced Infra-Lightweight Concrete (ILC). In: ACI Structural Concrete. March-April 2019

Schlaich, Mike; Gruber, Doris; Popp, Bernhard: Infraleichtbeton – Leichter als Wasser. In: Deutsche BauZeitschrift (2019), Nr. 2, S. 62–65

Schlaich, Mike (Hrsg.); Leibinger, Regine (Hrsg.); Lösch, Claudia; Rieseberg, Philip: Infraleichtbeton: Handbuch für Entwurf, Konstruktion und Bau. Berlin: Fraunhofer IRB Verlag, 2018

Schlaich, Mike; Hückler, Alex: Infraleichtbeton: Reif für die Praxis. In: Beton- und Stahlbetonbau (2017), Nr. 12, S. 772-783

Schlaich, Mike; Hückler, Alex; Lösch, Claudia: Infra-Light Weight Concrete – A monolythic building skin. In: AUER, Thomas; KNAAK, Ulrich; SCHNEIDER, Jens (Hrsg.): Proceedings of Powerskin Conference. Delft: TU Delft Open, 2017, S. 293–304

LEIBINGER, Regine; Schlaich, Mike; Lösch, Claudia; Rieseberg, Philip; Ballestrem, Matthias: Infraleichtbeton im Geschosswohnungsbau (INBIG) : Abschlussbericht. Stuttgart: Fraunhofer IRB Verlag, 2017 (Forschungsinitiative Zukunft Bau F 3018)

Hückler, Alex ; Schlaich, Mike: Zur Biegung von Infraleichtbetonbauteilen – Werkstoff-, Verbund-, Trag- und Verformungsverhalten. In: Beton- und Stahlbetonbau 112 (2017), Nr. 5, S. 282–292

Hückler, Alex: Trag- und Verformungsverhalten von biegebeanspruchten Bauteilen aus Infraleichtbeton (ILC). Dissertation. 1. Auflage. Göttingen: Sierke Verlag, 2016

Lösch, Claudia; Rieseberg, Philip; Schlaich, Mike; LEIBINGER, Regine; BALLESTREM, Matthias: Infra-Lightweight Concrete in Multi-Story Residential Buildings. In: Economic Forum (Hrsg.): 10th Conference on Advanced Building Skins: 3-4 November 2015, Bern, Switzerland, S. 932–941

Hückler, Alex; Schlaich, Mike: Bond and deformation behaviour of reinforced Infra-Lightweight Concrete (ILC). In: Proceedings of fib Symposium 2015, Copenhagen, S. 116–117

Hückler, Alex; Schlaich, Mike: Infraleichtbeton – Forschung an der Technischen Universität Berlin. In: Baukammer Berlin – Nachrichten für die im Bauwesen tätigen Ingenieure (2015), Nr. 1, S. 21–24

Hückler, Alex; Schlaich, Mike: Low Tech Konstruktionen mit Infraleichtbeton: Diese Außenwand kann Multitasking. In: Deutsche BauZeitschrift (2013), Nr. 2, S. 84–86

Schlaich, Mike; Hückler, Alex: Infraleichtbeton 2.0. In: Beton- und Stahlbetonbau 107 (2012), Nr. 11, S. 757–766

El Zareef, Mohamed Ahmed Mohamed (Hrsg.): Conceptual and structural design of buildings made of lightweight and infra-lightweight concrete. Aachen : Shaker., 2010

Schlaich, Mike; El Zareef, Mohamed: Infraleichtbeton. In: Beton- und Stahlbetonbau 103 (2008), Nr. 3, S. 175–182